CMA D. ARGOUDELIS & CO S.A. Pioneers Maritime Automation Lab at BCA College!

October 4, 2023

CMA D. ARGOUDELIS CO S.A. Partnerships with ROBERT BOSCH GmbH as an Authorized Distributor

October 25, 2023DANFOSS Marine Solutions from the Authorized Distributor CMA D. ARGOUDELIS & CO S.A.!

How do you ensure that your systems are SOLAS 282 compliant? That is the question facing marine operators, shipbuilders, and engine constructors after IMO, IACS and CIMAC agreed on the unified interpretation of SOLAS 282 and on implementing the circular on all new builds after July 1, 2017.

SOLAS 282, which is now enforced by the three leading organizations, focuses on preventing and mitigating the serious effects of fires onboard ships.

To do so, the circular specifies that only metals with a melting point above 930°C can be used in risk areas such as engine, turbine, and gearbox installations.

The Safety of Life at Sea (SOLAS) convention is regarded as the most important of all international treaties concerning the safety of vessels. The main objective is to specify minimum standards for the construction, equipment, and operation of ships regarding safety.

The implementation of SC282 is driven by:

• IMO, International Maritime Organization

• IACS, International Association of Classification Societies • CIMAC, International Council on Combustion Engines

Do not compromise on safety in the engine room

Two out of three ship fires start in the engine room. This area is classified as Category “A” due to its inventory of combustible material, such as the engine, turbine, and gearbox. An engine room fire fed by oil and other flammable substances has the risk of spreading quickly and becoming a threat to the vessel and the crew.

According to Norske Veritas, more than 50 percent of fires within the engine room are caused by fuel or lubricating oil leaking onto hot surfaces. The bureau estimates that the direct costs of an engine room fire can climb as high as 4 million euro. The safety of the vessel and its crew depends on adequate fire prevention measures that prevent or mitigate the effect of a fire in the engine room. Oil leaks are often caused by failing pipes or components, and components made of aluminum alloys are often part of the problem because they melt at temperatures around 640-660°C – after just 5 to 10 minutes of fire.

The new standard: Resist fire for more than an hour

The use of aluminum components on engine, turbine, or gearbox installations has been controversial for years due to the relatively low melting temperature of the lightweight material, which may cause oil spills and accelerate the fire.

To deal with the problem, the SOLAS Circular 282 specifies that the housing and bodies of valves, switches, transmitters, filters, and strainers should be made of steel or another equivalent material with a melting point above 930°C and an elongation above 12 percent. The unified interpretation of the SOLAS Circular was implemented on vessels constructed after July 1, 2017. This means that external components such as test valves, fuel filter housings, pipes, etc., which are prone to release flammable substances in the engine room due to failure, have to be made of steel.

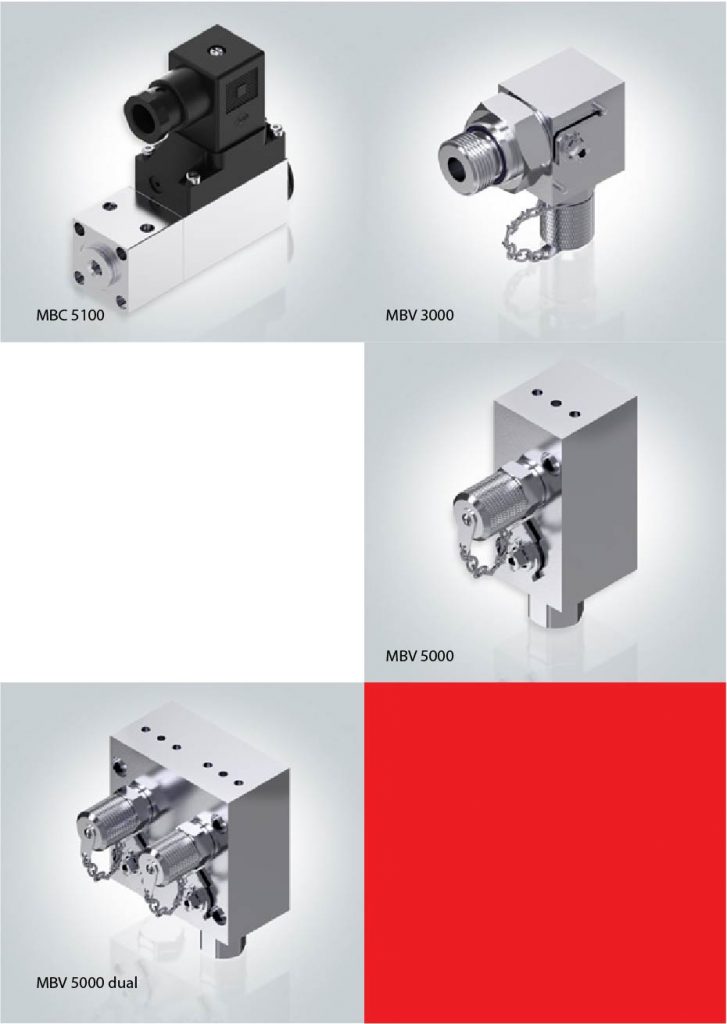

Comply with stainless steel components

Danfoss supports a fast implementation of the Unified Interpretation of SC 282 that is generally regarded as the most important of all the international treaties concerning safety at sea. To accommodate the requirements of SC 282, Danfoss offers a wide product program of stainless steel, comprising of:

• The MBC 5100 pressure switch with stainless steel process connection

• The MBV 5000 stainless steel block pressure test valve

• The MBV 3000 stainless steel test valve for pressure cartridge transmitters

• The MBS 3100/3300 stainless steel cartridge pressure transmitter

• The MBS 5100 pressure transmitter with stainless steel process connection • The MBV 2000 stainless steel one-way test valve

NEED MORE HELP?

Please call CMA’s SalesTeam

Tel. +30210 4615 831

Email: sales@cmagreece.com