CMA D. ARGOUDELIS & CO S.A. Partnerships with ASK Digital!

July 13, 2022

Burkert Process Control Valves for Marine & Industrial Applications

September 22, 2022Customized Automation Solutions for the Packaging & Printing Industry with FESTO products, from the Official Distributor in Greece CMA D. ARGOUDELIS & CO S.A.

Slimmer and shorter than ever before. Ideal for tight installation spaces. Extremely sturdy thanks to its resilient materials.

- Short variant of ISO cylinder DSNU

- Quick and easy installation, even in tight spaces

- Light weight

- Self-adjusting pneumatic end-position cushioning saves time during commissioning and adapts optimally to load and speed changes

- Piston rod with male thread

- For position sensing

- Variants recommended for production systems for manufacturing lithium-ion batteries

- Sustainable in production thanks to reduced use of materials

- Stroke 25 mm

- Piston diameter 32 mm

- Piston rod thread M10x1.25

- Cushioning Pneumatic cushioning, adjustable at both ends

- Mounting position optional

- Conforms to standard ISO 15552

- Piston-rod end Male thread

- Design Piston Piston rod Profile barrel

- Position detection Via proximity switch

- Conforms to standard EN 60947-5-2

- Symbol 00991702

- Approval RCM trademark c UL us listed (OL)

- CE mark (see declaration of conformity)To EU EMC Directive

- Rated operating distance 2 mm

- Assured operating distance 1.62 mm

- Reduction factors Aluminium = 0.4 Stainless steel St 18/8 = 0.6 Copper = 0.3 Brass = 0.5 Steel St 37 = 1.0

- Ambient temperature -25 °C … 70 °C

- Repetition accuracy with constant conditions 0.1 mm

- Switching output PNP

- Switching element function N/O contact

- Hysteresis 0.18 mm

- Max. switching frequency 3000 Hz

- Max. output current 200 mA

- Voltage drop 2 V

- Inductive protective circuit Integrated

- Short circuit current rating Pulsed

- Operational voltage range DC10 V … 30 V

- Residual ripple ± 10%

- Outside diameter 6 mm

- Flow-relevant bending radius 26 mm

- Inside diameter 4 mm

- Min. bending radius 10 mm

- Tubing characteristics Suitable for energy chains

- Temperature-dependent operating pressure -0.095 MPa … 1 MPa

- Temperature-dependent operating pressure -0.95 bar … 10 bar

- Temperature-dependent operating pressure -13.775 psi … 145 psi

- Approval German Technical Control Board (TÜV)

- Certificate issuing authority B 013277 0506 00

- Operating medium Compressed air to ISO 8573-1:2010 [7:-:-] Water as per manufacturer’s declaration at www.festo.com

- Fire test material UL94 HB

- LABS (PWIS) conformity VDMA24364-B2-L

Perfect compressed air preparation! With its large product range, highly functional components and a wide choice of services, the MS series from Festo offers a complete concept for compressed air preparation – for both standard applications and application-specific solutions.

- Grid dimension 40mm

- Predefined or freely configurable combinations of service unit components

- Depending on the application, combination of filter regulator, filter, lubricator, on/off valve, soft-start valve, branching module

Screw-in check valve.

- Valve function: non-return function

- Screw-in or in-line installation

- With connecting thread at both ends, push-in connector at both ends, thread/push-in connector

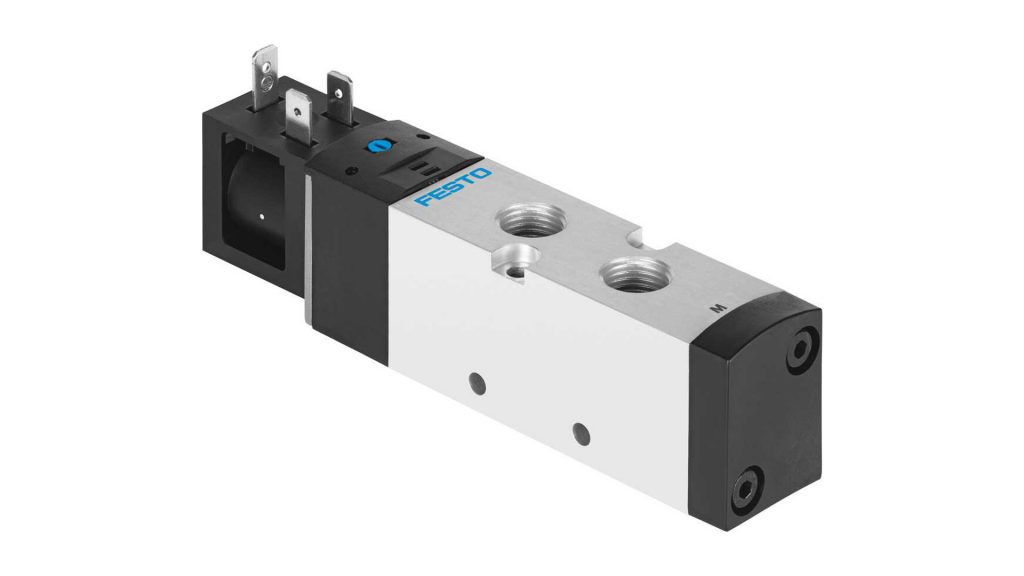

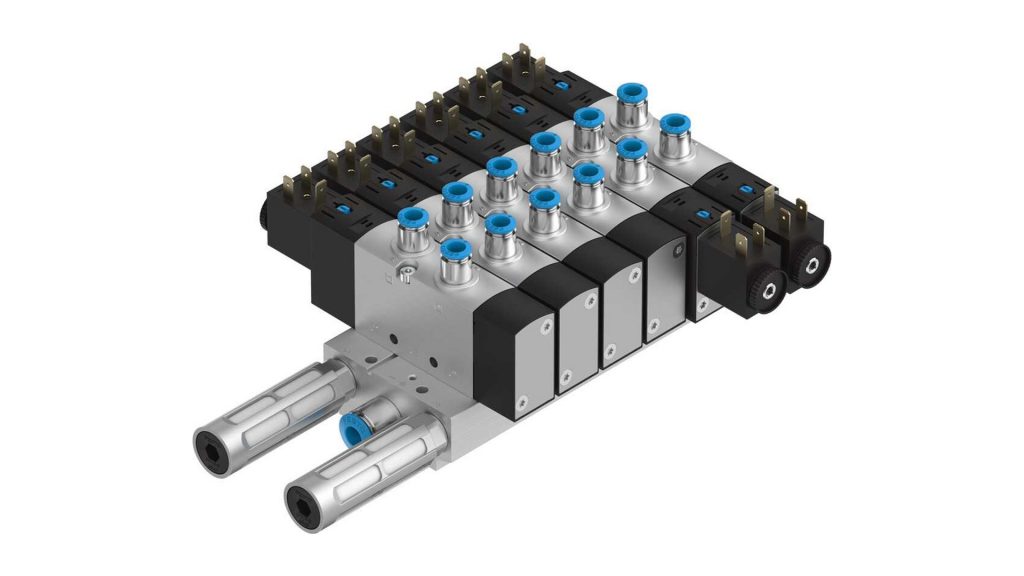

Sturdy solenoid valve that is easy to operate.

- Universal valve, sturdy and durable

- Low cost with no performance limitations

- Can be used as individual valves or manifold valves VTUS

- Valve size 26.5 mm

- Standard nominal flow rate 1000 l/min … 1300 l/min

- pneumatic working port G1/4 1/4 NPT QS-6 QS-8 QS-10 QS-1/4 QS-5/16 QS-3/8

- Operating pressure -0.09 MPa … 1 MPa

- Operating pressure -0.9 bar … 10 bar

- Electrical control Individual connection

- Max. number of valve positions 16

- Max. number of pressure zones 9

- Electrical I/O systemno

- Ambient temperature -10 °C … 50 °C

Push-in fitting, mini series QSM

- Mini series

- Compact for maximum component density in confined installation spaces

- PBT and nickel-plated brass

- Operating medium: compressed air, vacuum

- Brass, nickel-plated

- Sleeve

- Extension

- Double nipple

- Reducing nipple

- L-, T-, Y- or X-fitting

- Operating medium: compressed air, vacuum

NEED MORE HELP?

Please call CMA’s Sales Team

Tel. +30210 4615 831

Email: sales@cmagreece.com