LUMEL Environmental parameters data logger HT22IoT

April 15, 2021

CEP12 Electropneumatic Controller for Ships

April 22, 2021Bosch Rexroth EFC Series Frequency Converter

EFC Series

Frequency Converter for Industry

A member of Rexroth AE product family

Universal Development Platform

asy integration to Rexroth

Automation Project

Overview

The Rexroth EFC series frequency converter is a product for the worldwide market.

Certification of CE, UL, cUL, RCM, EAC TUV, RoHs, etc.,

Consolidated sales and service is provided worldwide.

Main Features

► Normal duty/heavy duty operation. (Above 5.5KW)

► High performance vector and torque technology (EFC 5610).

► Low frequency oscillation suppression and start with speed capture. Inversion forbidden, low voltage ride-through and swing frequency function.

► Counter function and energy savings calculator.

► Pulse input (50 kHz) and pulse output (32 kHz).

► Over-excitation braking, to reduce braking times up to 50 %.

► 24 V auxiliary power output for external devices.

► Indraworks for fast commissioning and software update.

Synchronous Motor Drives

► Except asynchronous motor, EFC 5610 drives synchronous motor.

Built-in mains filter

► Complies with EN61800-3 category C3 requirements.

► Shielding motor cable length: 15m (up to 4 kW), 30 m 5.5…18.5 kW), 50m (30…90 kW), 75 m (110…160 kW).

► EMC filter can be disconnected by EMC screw.

► Built-in DC reactor of EFC 5610 30 kW and above.

Safety Torque off(STO)

► Class 0 cutoff refers to EN60204-1 standard, and got SIL3 certificate.

Up to 45 °C ambient temperature without derating

Additional communication options

► In addition to PROFIBUS DP and CANopen also a SERCOS III, PROFINET IO, Ethernet IP, Modbus TCP, EtherCAT are available. Especially, the Rexroth exclusive SERCOS III communication function Communication rate could be microsecond level.

Portfolio

EFC 3610 Universal FC

■ 1X AC 230V 0,4-2,2 kW 3X AC 400V 0,4-22 kW

■ V/F Control

■ Asynchronous Motor

■Overload Capacity:Heavy Load:150 %, 60 s; Light Load:120 %, 60 s

■Frequency Range: 0 k … 400 kHz

■Speed Range 1:50

■Start Torque: 3 Hz 150 % 1.5 Hz 100 %

EFC 5610 High Performance FC

■ 1X AC 230V 0,4-2,2 kW 3X AC 230V 0,4-11 kW

3X AC 400V 0,4-160 kW

■ V/F SVC FOC Control (Speed / Torque)

■ Asynchronous ,Synchronous Motor

■ Overload Capacity :Heavy Load:150 %, 60 s; 200 %, 1 s Light Load:120 %, 60 s

■ Frequency Range: 0 k … 400 kHz

■ Speed Range 1:200

■ Start Torque :0.5Hz 200 %

Application Fields

HVAC – Fans, pumps, air conditioning

Energy savings calculator

► Keeps track of the achieved energy savings.

Life time reminder

► Reduces downtime by helping to organize the maintenance

schedule.

Speed tracing

► For smooth catching and restarting of a running fan.

Dry pump protection

► Automatically detects a dry running pump to protect the

equipment.

Pump cascading

► Use Application Specific Firmware and relay card,

4 maximum pumps could be circularly controlled by

frequency converter.

Textile and Dyeing – Heat setting stenter, twister, air-flow spinning

Smart cooling concept

► Double duct design isolates heat sink and semiconductor to prevent semiconductor from pollution.

► No cooling fan up to 1.5 kW and detachable cooling fan above 1.5 kW for cotton fiber easy clean.

Import PCBA coating

► Coating materials is made in Germany, enhanced anticorrosion in high temperature and humidity.

Low voltage ride-through

► Derating output when voltage reduced on power grid.

DC generatrix

► DC generatrix operation to reduce the technical influence from instable power supply, and save energy through load sharing.

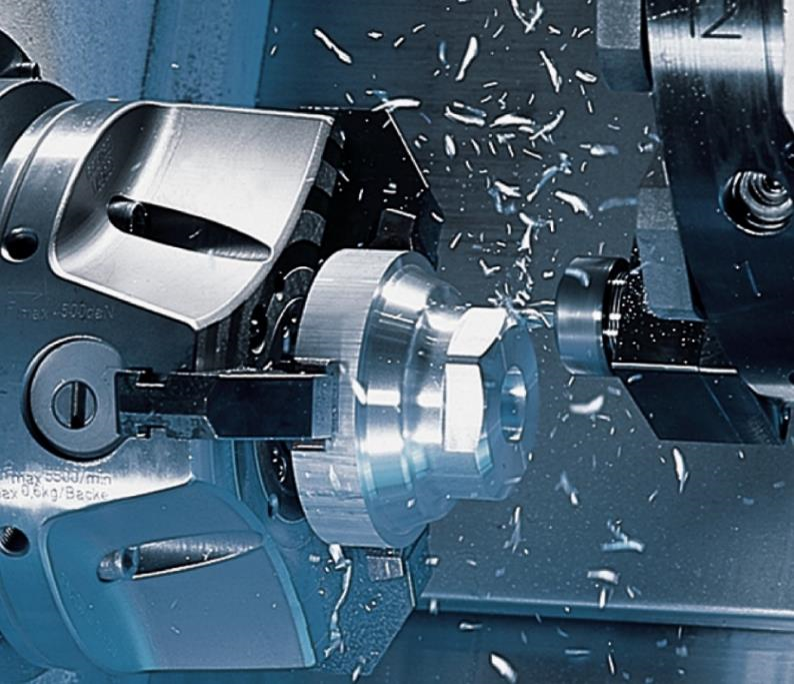

Metal processing machinery – Lathe, grinder, drill, planer, borin

Compact design

► DIN rail and side by side mounting to save space.

High start torque

► To meet the process demand of high strength metal cutting, avoid overcurrent and overload during low speed operation .

Quick and dynamic response

► Accurate speed control for highly smoothness and quality especially for concavo-convex workpiece surface.

Over excitation braking

► Can help to reduce braking times up to 50 %, without an external break resistor.

Safety Torque off(STO)

► Frequency converter false tripping prevent for operation and maintenance safety.

Food and packaging – Conveyor, blow molding, blender, cutter, labeling

Quick connectors and DIN rail mounting (up to 7.5 kW)

► Quick and easy installation and maintenance.

Counter function

► Built-in Counter to realize the classification and packing of food & drink industry.

Removable control panel

► Parameter copy function for efficient commissioning of multiple drives.

► Remote panel support for convenient and safe monitoring and operation.

Integrated sequence control (16 steps)

► Multi-stage speed control without an additional PLC.

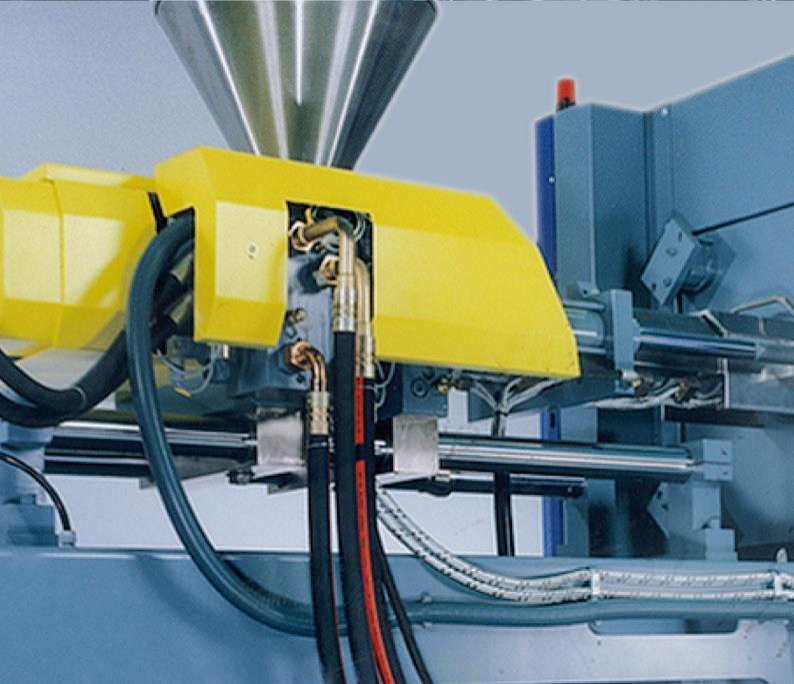

Rubber and plastic machinery – Scroll extruder, pelletizer, bagging

Compact design

► DIN rail mounting (up to 7.5 kW) and side by side mounting (up to 22 kW), to save cabinet space.

High start torque, 200 % at 0.5 Hz

► To ensure the extruder can start up and operate during the uneven heating temperature environment.

High control accuracy, fast dynamic response

► Precise control is to ensure the material thickness evenly, in order to save cost and ensure the quality of products.

Torque limit and slip compensation

► Especially used for constant output torque. Minimize the torque fluctuation and improve the extrusion process quality.